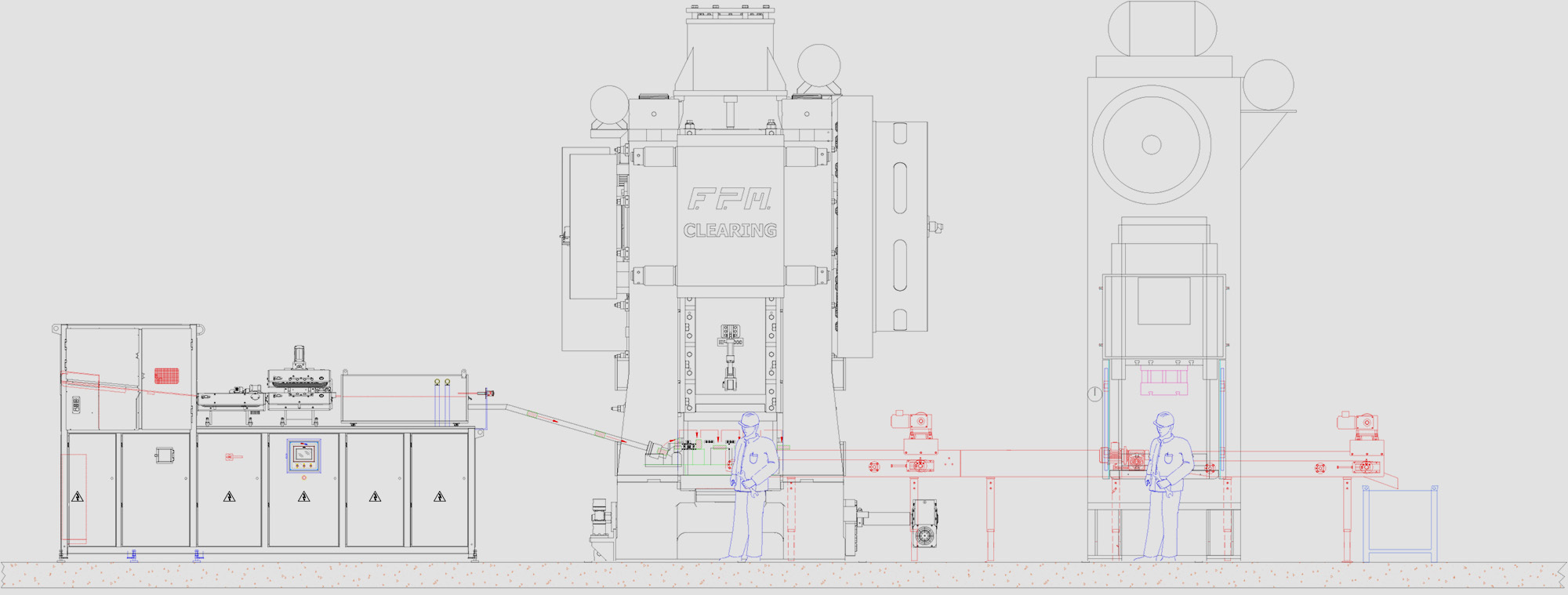

Complete steel

forging lines

Forging presses and friction screw presses can be integrated into production lines for steel and titanium, fully automatic and complete with robots.

The forging systems can be composed by cutting machines and billet shears, gas heating furnaces or induction furnaces, electrical-upsetting machines, mechanical presses up to 6000 ton, friction screw presses up to 3000 tons, hammers, trimming presses and calibration presses.

The overhauling and modernizations of the machines are combined with a deep knowledge of the process.

In order to meet the production needs of the modern steel forging plant according to Industry 4.0.

Sawing machines and rod-shears

The cutting of the forging rods takes place both with blade sawing machines and with mechanical or hydraulic shears. We can supply completely overhauled machines.

Heating furnaces

Thanks to our partner company FARM BRASS we can supply automatic billet heating systems, both gas and induction, both used and new.

Mechanical presses

40 years of work lead us to overhaul presses from all the most famous presses manufacturer for hot forging. This overhauling activity allowed us to experiment, study and improve all the different productive solutions on the market, and subequently to gain a huge technical background even in the manufacturing of completely new presses, and to add important improvements in case of overhauled machines, installing accessories and new systems, designed on the needs of each single customer and single machine.

Friction screw presses

FPM engineers, produces or overhauls any type of friction screw press, from 300 Ton to 4000 Ton of power. The friction screw press models produced or overhauled range from the smallest disc models with two tie-rods, to the largest models with 4 tie-rods up to the direct-drive type.

Dies and equipments

In cooperation with customers, where required, we can supply forging and trimming dies, developed on specific equipments needs.

Loading and unloading automations

Whether rotary or linear arms or robots, we can always suggest the best loading, unloading and handling solution, for billets and forged pieces.

Trimming presses

We can supply any type of press for deburring and trimming of the pieces, both hydraulic or mechanic type. They can be automatic or with manual loading.

Shot blasting systems

Where needed we can supply automatic machines for shot-blasting and sand-blasting of the forged pieces.

Heat treatment furnaces

Our partner company FARM BRASS manufactures specific tailor made systems for heat treatment in an uncontrolled atmosphere or quenching in water, for forged pieces.

Software and automation and supervision systems

In our systems we always create both the electrical system and the programming of the PLCs and supervision software.

Electric upsetters

FTB, our sister company, designs and builds electric upsetters for partial heating and pre-forming of billets, with manual or automatic loading.