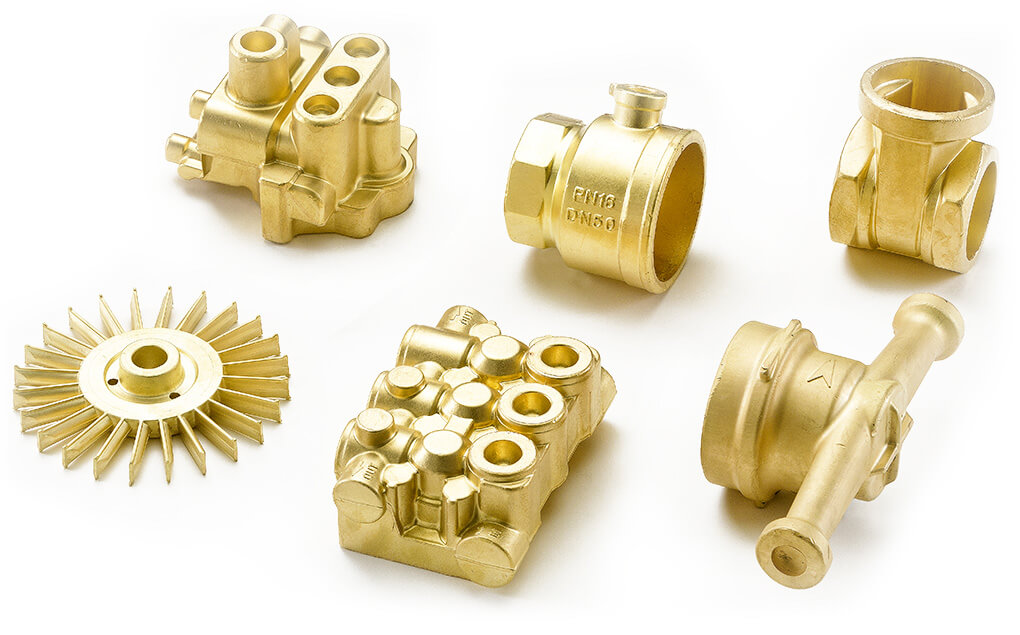

Complete lines for

brass hot forging

The design of new system for brass and copper alloys hot forging begins from the feasibility study, moving from the engineering of the production process, to the production and integration of all the machines composing the plant, up to the installation and start-up.

The research and development department is guided by a real experience in the forging field.

To this, we add our passion to find solutions and productive assets for the industrialization needs for each product.

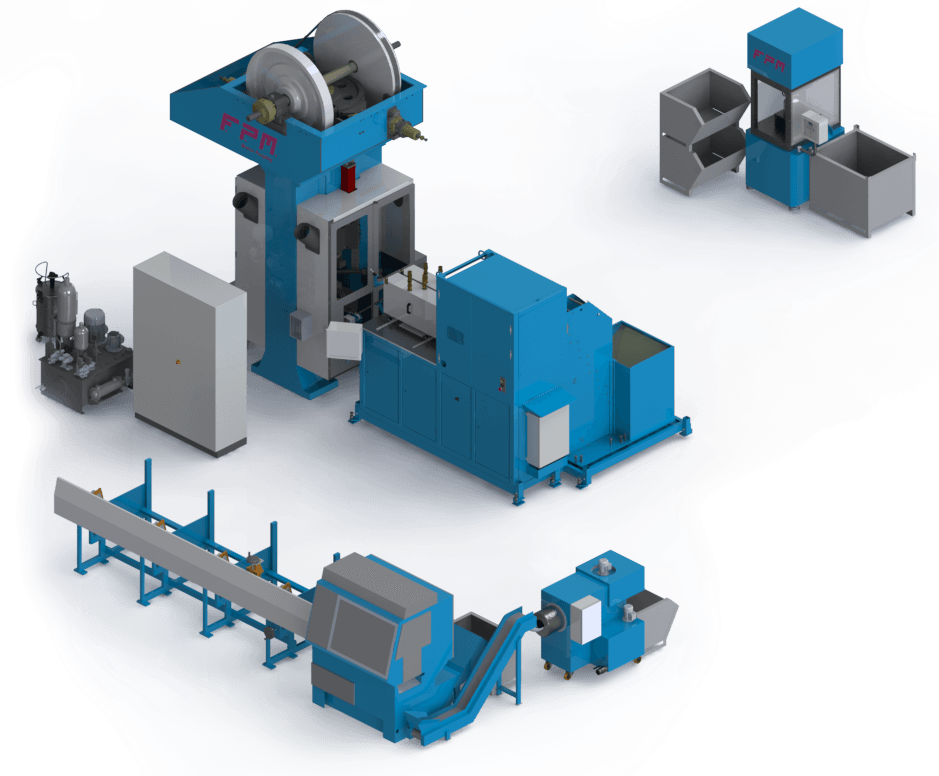

In the field of brass and copper forging we have 40 years of expertise, the knowledge we have refers to hundreds of designed and installed production lines, both with mechanical presses and friction screw presses. We can supply new lines, enterely manufactured by us, or completely overhauled lines. In this sense we are able to offer complete systems that can include:

We can supply new lines, enterely manufactured by us, or completely overhauled lines.

In this sense we are able to offer complete systems that can include:

Sawing machines for brass rods

The cutting of the brass rods is by means of machine with automatic loading, cutting of one or two bars, automatic rejection of initial and final part of the rod, automatic waste of the brass shavings.

Washing machines for billet

For some application we can supply system for washing and drying billets, in order to remove brass cutting shavings and various impurity.

Graphitizing machines

For a uniform application of graphite on the billets to be forged, we can manufacture automatic systems for graphitizing, with drums, both in line or self-standing machines.

Heating furnaces

Thanks to our partner company FARM BRASS we can supply automatic billet heating systems, both gas and induction.

Mechanical presses

40 years of work lead us to overhaul presses from all the most famous presses manufacturer for hot forging. This overhauling activity allowed us to experiment, study and improve all the different productive solutions on the market, and subequently to gain a huge technical background even in the manufacturing of completely new presses, and to add important improvements in case of overhauled machines, installing accessories and new systems, designed on the needs of each single customer and single machine.

Friction screw presses

FPM engineers, produces or overhauls any type of friction screw press, from 300 Ton to 4000 Ton of power. The friction screw press models produced or overhauled range from the smallest disc models with two tie-rods, to the largest models with 4 tie-rods up to the direct-drive type.

Dies and equipments

In cooperation with customers, where required, we can supply forging and trimming dies, developed on specific equipments needs.

Loading and unloading automations

Whether rotary or linear arms or robots, we can always suggest the best loading, unloading and handling solution, for billets and forged pieces.

Trimming presses

We can supply any type of press for deburring and trimming of the pieces, both hydraulic or mechanic type, both with rotary or fixed table. They can be automatic or with manual loading.

Shot blasting systems

Where needed we can supply automatic machines for shot-blasting and sand-blasting of the forged pieces.

Heat treatment furnaces

Our partner company FARM BRASS manufactures specific tailor made systems for heat treatment in an uncontrolled atmosphere or quenching in water, for forged pieces.

Software, automation and supervision systems

In our systems we always create both the electrical system and the programming of the PLCs and supervision software.